Some Of Premier Aluminum Llc

Some Of Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Can Be Fun For Anyone

Table of ContentsSome Known Factual Statements About Premier Aluminum Llc The Buzz on Premier Aluminum LlcUnknown Facts About Premier Aluminum LlcWhat Does Premier Aluminum Llc Mean?

(https://www.edocr.com/v/0onvglma/garymartin53403/premier-aluminum-llc)Using low price and unqualified providers can create high quality concerns, and lost time and cash in the long run. To help you through the process, right here are some points to consider when picking the right metal spreading provider.

A business that only utilizes the financial investment casting procedure will attempt to offer you on why that process is best for your application (Aluminum Foundry). However what if using the sand casting procedure is best for you and your demands? Rather, search for a vendor that supplies a variety of casting procedures so the very best choice for YOU is picked

If dealing with a solitary resource for all of your casting needs is very important to you, the provider needs to be diverse in its capacities. When combined with various other integrated capacities, this can assist streamline and press the supply base. When picking the appropriate spreading distributor, careful factor to consider needs to be provided to top quality, service, and rate.

Everything about Premier Aluminum Llc

Purchasers progressively select spreading providers who have machining abilities. This can prevent problem if defects are discovered throughout machining. If a third event is machining, it might result in "finger-pointing" concerning that is at mistake. Is it a casting issue or a machining concern? If the spreading supplier discovers an issue during machining, the trouble is fixed quicker without any dispute over whose mistake it is.

What do you need from your casting supplier? Are you looking for someone to simply supply a steel part to your front door or do you require more?

Some foundries are restricted or specialized. Make sure the supplier can satisfy all your product or alloy demands to get rid of the requirement for several vendors.

An Unbiased View of Premier Aluminum Llc

Research the distributor's site. Talk to a sales rep or company associate.

Aluminum is also lightweight and has excellent deterioration resistance, making it excellent for applications where weight and resilience are essential aspects. Furthermore, aluminum spreading is an economical technique of manufacturing, as it needs much less power and resources than various other approaches. Iron casting, on the other hand, involves putting molten iron into a mold to create a wanted form.

The Premier Aluminum Llc Diaries

Iron spreading is additionally able to stand up to heats, making it appropriate for use in applications such as engine parts and commercial machinery. However, iron spreading can be much more costly than aluminum casting as a result of the higher cost of basic materials and the power called for to thaw the iron. When deciding in between light weight aluminum spreading and iron casting, it is vital to think about the certain requirements of the application.

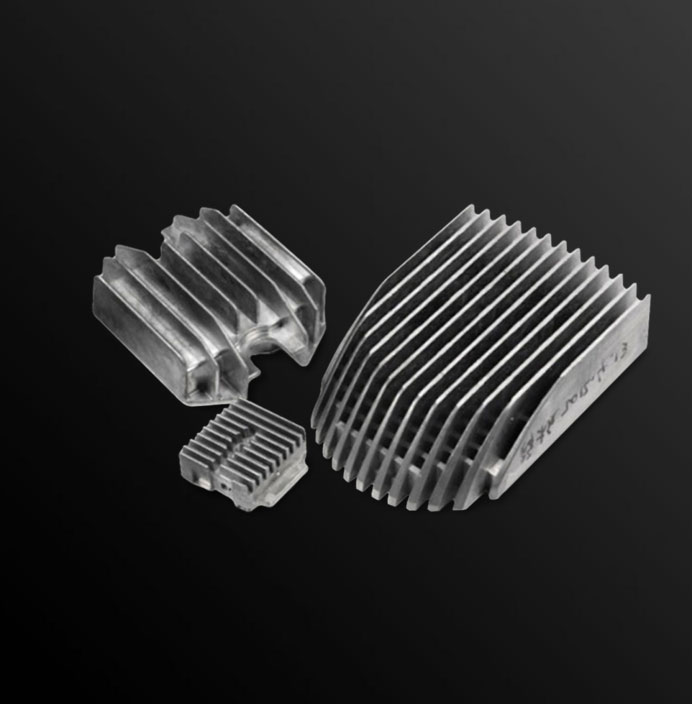

In final thought, both light weight aluminum casting and iron casting have their own special advantages and disadvantages. There are 3 sub-processes that fall under the category of die spreading: gravity die casting (or irreversible mold casting), low-pressure die casting and high-pressure die casting. To get to the completed product, there are three main alloys utilized as die casting material to choose from: zinc, light weight aluminum and magnesium. Report this page